Medical

At Laxmi Hitech Solutions, we understand the critical demands of the medical industry, where precision, reliability, and cleanliness are paramount. Our specialized plastic moulding services cater to the intricate needs of medical device manufacturers, ensuring that every product meets the highest standards of quality and performance

Medical Industry Solutions

Dust Particle

Control

Maintaining a contaminant-free environment is essential in medical manufacturing. Our state-of-the-art facilities are equipped with advanced dust particle control systems, ensuring that every product we create is free from contaminants and safe for medical use.

Critical Multi-Cavity

Dies

We specialize in creating complex multi-cavity dies, such as our 128-cavity die for needle hubs ranging from 18-22 gauge. These high-precision dies enable us to produce large volumes of components with exceptional consistency and accuracy, meeting the rigorous demands of the medical industry.

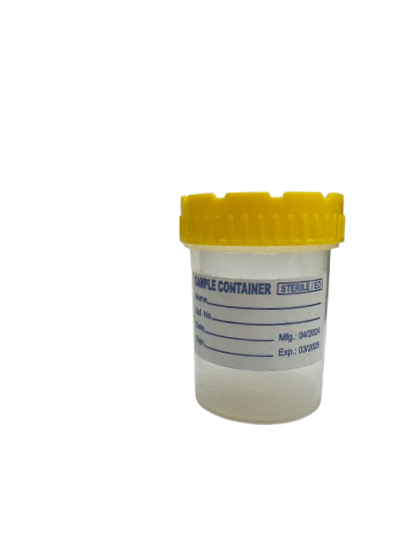

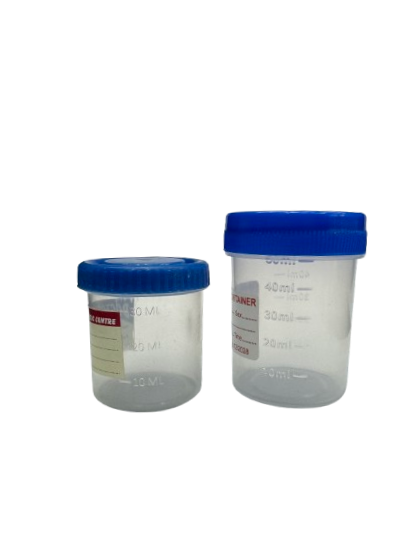

Clean Room

Manufacturing

Our clean room manufacturing capabilities ensure that all medical components are produced in a controlled environment, free from contaminants. This is crucial for maintaining the sterility and quality of medical products, such as needle hubs and other critical components.

Fitment Locking and

Pressure Testing

We provide comprehensive solutions that include fitment locking and opening with pressure testing. This ensures that all components fit perfectly and function reliably under pressure, meeting the stringent requirements of medical applications.

Customization and

Color Options

Understanding the need for customization in the medical field, we offer a range of color options and material guidance to suit specific applications. Whether it's for identification, aesthetic purposes, or functionality, our team can help you select the right materials and colours to meet your needs.